In the precise world of gas chromatography (GC) analysis, the integrity of the final result is only as good as the sample introduced into the instrument. For volatile organic compounds (VOCs) present in solid or liquid matrices, Headspace Sampling has long been established as the preferred sample introduction technique. It offers a cleaner, more efficient, and reproducible alternative to direct liquid injection or complex solvent extraction. Today, the advancement towards Automatic Headspace Sampler technology represents a significant leap forward, transforming GC workflows across industries from food and beverage to environmental and pharmaceutical testing.

Traditional manual headspace methods, while effective in principle, are often plagued by inconsistencies, low throughput, and the potential for human error. An Automatic Headspace Sampler elegantly addresses these challenges by automating the entire sample preparation and injection sequence. This sophisticated Headspace Sampling Equipment is designed to heat, equilibrate, pressurize, and transfer the vapor phase from a sealed sample vial directly into the GC inlet with remarkable precision. The automation ensures that every sample undergoes an identical process, eliminating variables and delivering exceptionally reproducible data. This is why industry experts and laboratories increasingly recommend choosing an automated system over manual methods.

The core advantage of automation lies in its profound impact on laboratory efficiency and data reliability. Once an analyst loads a tray of samples, the system operates unattended, seamlessly managing heating, pressure equilibration, and injection for dozens of samples. This frees up valuable technician time for other critical tasks and allows for overnight operation, dramatically increasing instrument utilization and laboratory throughput. More importantly, it enforces strict methodological consistency. Parameters such as incubation temperature, equilibration time, pressurization level, and injection duration are controlled with digital accuracy for every single vial. This leads to a drastic reduction in relative standard deviation (RSD), making results more trustworthy and comparable over time, which is crucial for quality control and research.

This consistency is paramount in applications like food safety and flavor analysis. A dedicated Headspace Sampler for Food Testing must handle diverse samples—from packaging materials for migrant studies to beverages for residual solvent analysis or solid foods for contamination screening—with absolute reliability and no cross-contamination. Automated systems excel here. They utilize high-inertia, deactivated sample pathways and often feature intelligent diagnostics to prevent errors, such as automatically skipping empty vial positions and halting upon detection of a mechanical fault to protect both the samples and the hardware.

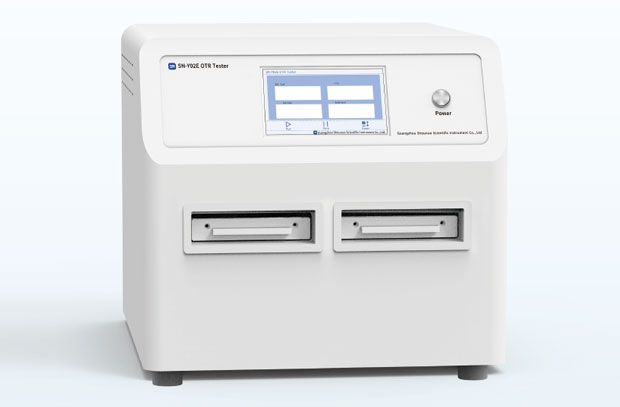

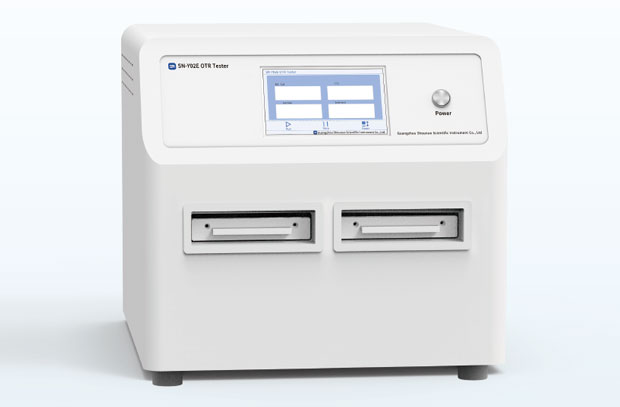

When considering an upgrade to automated headspace technology, the SN-DK3 Fully Automatic Headspace Sampler from Guangzhou Shounuo Scientific Instrument Co., Ltd. stands out as a robust and user-centric solution. Designed specifically to pair with gas chromatographs, this system embodies the key benefits discussed. It streamlines workflow with a clear interface and one-touch start, automating heating, needling, sampling, injection, and even the triggering of the GC and data system. Its capacity for 20 samples per run ensures high throughput for routine analysis.

The SN-DK3 is engineered for precision and durability. It employs a classic positive pressure sampling method with a six-port valve and loop system, minimizing dead volume for sharp, accurate injections. All fluid paths are made of imported high-inertia, deactivated tubing to prevent carryover and adsorption. Crucially, its design ensures that the valve and transfer lines are uniformly heated, eliminating any cold spots that could compromise sample integrity. Built with a rigid yet lightweight aluminum frame and featuring all-electric actuation (requiring no external drive gases), it is both safe and convenient to operate. Furthermore, its strong compatibility allows for easy connection and synchronized operation with most major GC brands globally.

In conclusion, integrating an Automatic Headspace Sampler into your GC system is not merely an incremental upgrade; it is a strategic decision to enhance data quality, operational efficiency, and methodological rigor. By automating a critical yet variable-prone step, laboratories can achieve new levels of reproducibility and throughput. For those seeking a reliable and feature-rich solution, exploring the capabilities of dedicated systems like the SN-DK3 from Guangzhou Shounuo Scientific Instrument Co., Ltd. offers a clear path to modernizing your analytical capabilities and ensuring your results stand up to the highest standards of scrutiny.