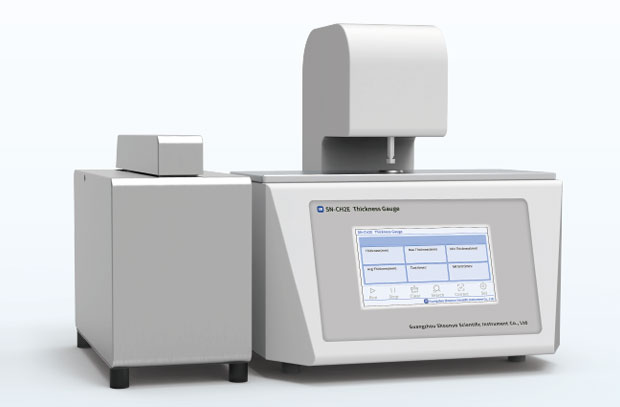

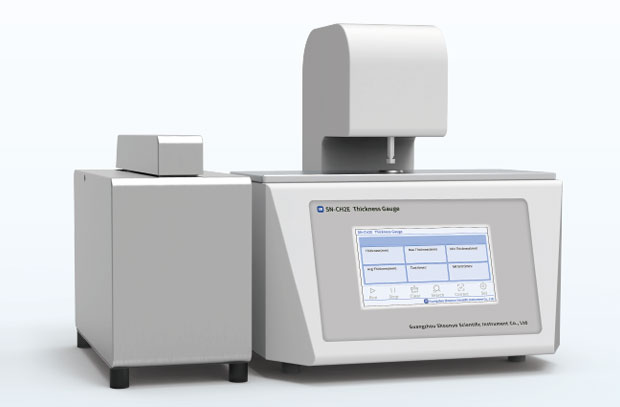

In the fast-paced and highly competitive world of flexible packaging, maintaining consistent product quality is not just an objective; it is a fundamental requirement for brand reputation, cost-efficiency, and customer satisfaction. Among the suite of instruments dedicated to quality assurance, the Electronic Thickness Gauge has emerged as an indispensable device. This precision tool plays a pivotal role in ensuring that materials such as films, laminates, foils, and papers meet exact specifications throughout the manufacturing and conversion processes.

But what specific role does an Electronic Thickness Gauge serve? Primarily, it provides fast, accurate, and non-destructive measurement of material thickness. In flexible packaging, the uniformity of material thickness is directly linked to critical performance attributes. A consistent thickness ensures proper barrier properties against oxygen and moisture, maintains desired tensile strength, and guarantees optimal performance on high-speed filling and sealing machines. Variations in thickness, even as minute as a few microns, can lead to weak seals, compromised product protection, and ultimately, waste and customer complaints. By integrating a reliable Thickness Gauge for Material into their quality control protocols, manufacturers can monitor production in real-time, making immediate adjustments to extrusion, coating, or lamination processes to correct any deviations.

The decision to utilize a modern Thickness Testing Instrument goes beyond simple measurement. It is a strategic move towards proactive quality management. Unlike manual methods or older tools, an electronic gauge offers unparalleled repeatability and precision. This data-driven approach allows producers to minimize material usage—a significant cost factor—without sacrificing performance. By ensuring every micron of material is used effectively, companies achieve substantial savings on raw materials like polymers and aluminum. Furthermore, consistent thickness is often a non-negotiable criterion in contracts with major brand owners and retailers. Providing certified data from a calibrated Electronic Thickness Gauge builds trust and demonstrates a commitment to excellence, strengthening business partnerships.

In practical terms, operators across the soft packaging industry use these instruments at various stages. Incoming raw material inspection verifies supplier consistency. In-process checks on the production floor prevent large batches of off-spec material from being produced. Finally, finished goods inspection ensures the product shipped to the client meets all agreed-upon parameters. The versatility of a Thickness Gauge for Material allows it to be used on single layers or final laminated structures, making it a universal tool in the QA laboratory.

The shift towards sustainability and higher performance standards in packaging further underscores the importance of precise thickness control. Thinner, yet stronger materials are being developed to reduce environmental impact. Only with a sophisticated Thickness Testing Instrument can manufacturers confidently navigate this trend, ensuring that lightweighting initiatives do not come at the cost of package integrity.

In conclusion, the Electronic Thickness Gauge is far more than a simple measuring device in the soft packaging sector. It is a cornerstone of quality control, a tool for cost reduction, and an enabler of innovation. For any manufacturer aiming to deliver reliable, high-performance, and efficient packaging solutions, investing in and routinely using a precision Thickness Testing Instrument is not merely an option—it is an essential practice for operational success and market competitiveness.