Industry News

-

Time:28.01.2026Learn about the Film Dart Drop Impact Test, a key method for measuring plastic film impact resistance per ASTM D1709 & ISO 7765-1. Discover how dart drop testers ensure packaging quality, safety, and compliance in material testing labs.

-

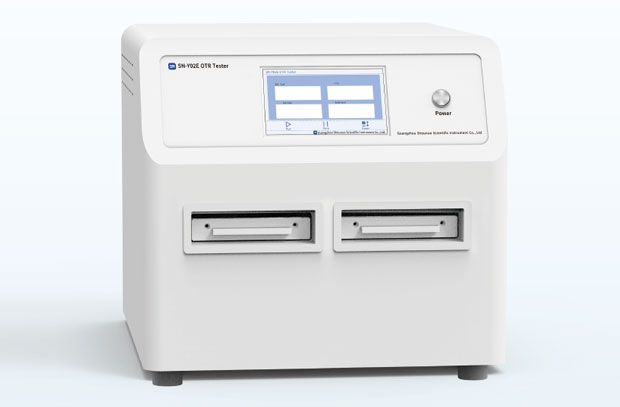

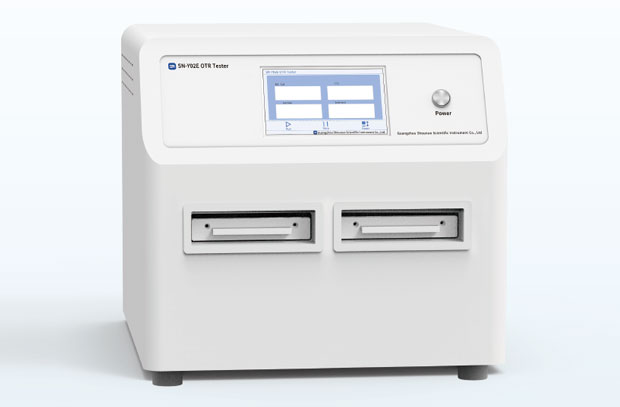

Time:14.01.2026In the packaging industry, the integrity of a material’s barrier against gases is paramount for product preservation and shelf life. Reliable measurement of oxygen ingress is a fundamental laboratory requirement. For labs conducting packaging research, quality control, and compliance testing, selecting a high-performance Oxygen Transmission Tester is a critical decision.

-

Time:25.12.2025In the precise world of gas chromatography (GC) analysis, the integrity of the final result is only as good as the sample introduced into the instrument. For volatile organic compounds (VOCs) present in solid or liquid matrices, Headspace Sampling has long been established as the preferred sample introduction technique. It offers a cleaner, more efficient, and reproducible alternative to direct liquid injection or complex solvent extraction.

-

Time:17.12.2025Compare Isostatic vs. Manometric OTR testers. This guide helps you choose the right oxygen transmission rate analyzer based on your materials (films, bottles) and budget. Learn key differences in method, accuracy, cost, and applications.

-

Time:15.12.2025In the competitive world of packaging, film, and plastic manufacturing, ensuring material toughness is non-negotiable. Product failures during transit or use are costly and damage brand reputation. To quantify and guarantee impact resistance, industry professionals rely on precise, reliable equipment. This guide delves deep into the Electronic Pendulum Impact Tester, explaining its advanced workings and providing a clear framework for selecting the perfect instrument for your lab.

-

Time:09.12.2025In the competitive world of polymer manufacturing and packaging, ensuring material consistency is non-negotiable. The Melt Flow Index Tester stands as a cornerstone instrument for quality control laboratories, providing critical data on the flow properties of thermoplastics. This essential device measures the Melt Flow Rate (MFR) or Melt Volume Rate (MVR), which are key indicators of a polymer's viscosity and molecular weight.

-

Time:04.12.2025In the competitive world of soft packaging, where product freshness, safety, and shelf appeal are paramount, the strength and reliability of every seal are non-negotiable. A single weak seal can lead to product contamination, spoilage, and devastating brand damage. This is where the Heat Seal Tester transitions from a quality control tool to an indispensable guardian of packaging integrity and brand reputation. This instrument is fundamental for any manufacturer committed to delivering consistent, secure, and high-performing flexible packaging.

-

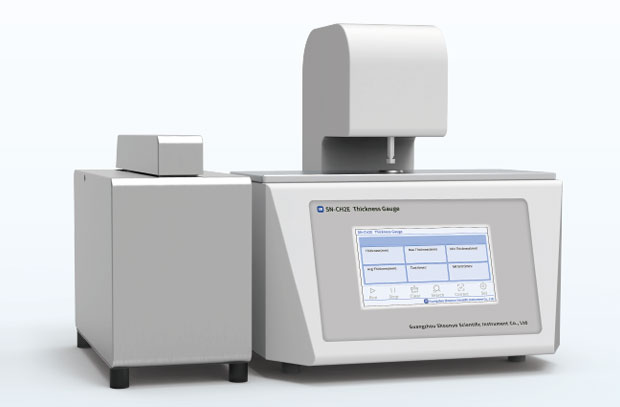

Time:02.12.2025In the fast-paced and highly competitive world of flexible packaging, maintaining consistent product quality is not just an objective; it is a fundamental requirement for brand reputation, cost-efficiency, and customer satisfaction. Among the suite of instruments dedicated to quality assurance, the Electronic Thickness Gauge has emerged as an indispensable device. This precision tool plays a pivotal role in ensuring that materials such as films, laminates, foils, and papers meet exact specifications throughout the manufacturing and conversion processes.

-

Time:27.11.2025In the world of packaging and material testing, the Drop Dart Impact Meter plays a crucial role in evaluating the durability and performance of various flexible materials. This instrument is widely recognized for its precision in measuring the impact resistance of films, sheets, and other packaging components. By simulating real-world conditions, it helps manufacturers ensure their products meet quality standards and withstand handling, transportation, and storage stresses.

-

Time:25.11.2025In the world of packaging and material manufacturing, ensuring the durability and integrity of materials like paper, cardboard, plastics, and textiles is a fundamental requirement. This is where the Electronic Tearing Tester becomes an indispensable tool for quality assurance laboratories and production facilities. This instrument provides critical data that directly influences product quality, performance, and customer satisfaction.