If you're in the business of ensuring product freshness, shelf life, and quality, you've likely heard the term "Oxygen Transmission Rate Tester" (OTR Tester). But here's the real question: is it just a box you tick for quality control, or is it the most critical instrument on your production floor?

Let's cut through the jargon. An OTR Tester isn't just another piece of lab equipment. For anyone involved in food packaging, pharmaceuticals, or advanced materials, it's your first and last line of defense against spoilage, degradation, and costly product recalls.

The Silent Threat: What is Oxygen Transmission Rate?

Simply put, Oxygen Transmission Rate (OTR) is the steady-state rate at which oxygen gas permeates through a specific area of a packaging material over a 24-hour period. It's measured in cc/m²/day (or cc/pkg/day for finished packages).

Think of it this way: even the most robust-looking plastic film or laminate is like a microscopic sponge for gases. Oxygen molecules, tiny and persistent, will eventually find their way through the polymer matrix. The OTR value quantifies this "leakiness." A high OTR means oxygen gets through easily, spelling disaster for oxygen-sensitive products. A low OTR indicates a high barrier, preserving your product's integrity.

This is where the Oxygen Transmission Rate Tester comes in. It’s the instrument that gives you a hard number, replacing assumptions with actionable data.

How an OTR Tester Actually Works (The Practical View)

While the underlying science is complex, modern testers have made the process remarkably straightforward. The most common method used in the industry is the coulometric sensor method. Here’s a breakdown without the overwhelming physics:

-

Sample Mounting: A precise sample of your packaging film is securely sealed between two chambers.

-

Creating a Gradient: One chamber receives a continuous flow of high-purity oxygen (the test gas). The other chamber gets a stream of oxygen-free carrier gas (like nitrogen).

-

The Journey: Oxygen molecules permeate through the film from the high-concentration side to the low-concentration side.

-

Detection & Measurement: The permeated oxygen is carried by the nitrogen gas directly to a highly sensitive coulometric sensor. This sensor generates an electrical current precisely proportional to the amount of oxygen arriving.

-

Calculation: The instrument’s software calculates the exact OTR value based on this current, the film area, and the environmental conditions.

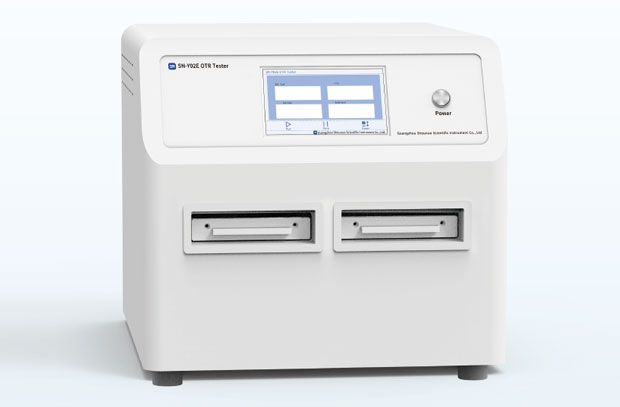

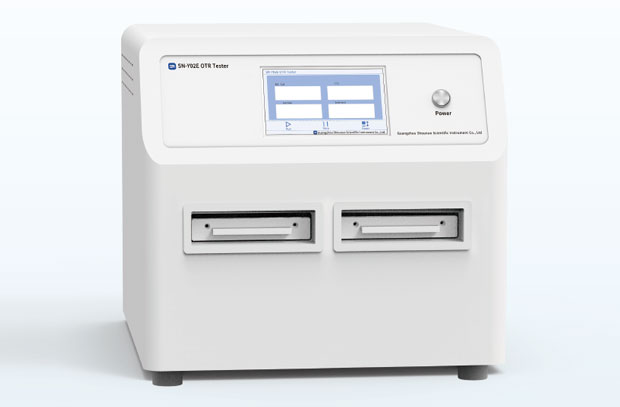

Modern Oxygen Transmission Rate Testers, like the ones we work with, are fully automated. You set it up, load your samples, and get precise, repeatable results without manual calculations. This reliability is non-negotiable.

The Real-World Impact: Why You Can't Afford to Skip OTR Testing

Investing in a reliable OTR Tester isn't an expense; it's a strategic move that pays for itself. Here’s how:

-

Predict & Extend Shelf Life: How long will your organic coffee stay fresh? Will your premium snack chips stay crisp? An OTR Tester gives you the data to answer these questions scientifically, allowing you to print accurate "best before" dates and reduce food waste.

-

Material Selection & Validation: Is that new, cheaper film supplier offering the same barrier protection? Don't take their word for it. Test it. An OTR Tester empowers you to qualify new materials confidently and catch inconsistencies before they ruin a production batch.

-

R&D and Innovation: Developing a new sustainable packaging solution? A biodegradable film might have different barrier properties. Use an OTR Tester to guide your R&D, optimize multilayer structures, and ensure your eco-friendly package also performs its primary job: protection.

-

Prevent Catastrophic Failure: For the pharmaceutical industry, oxygen can degrade active ingredients, rendering life-saving drugs ineffective. Rigorous OTR testing of blister packs and vials is a critical part of GMP (Good Manufacturing Practice).

Choosing the Right Oxygen Transmission Rate Tester: Key Considerations

Not all testers are created equal. When evaluating an OTR Tester, look beyond the price tag. Focus on:

-

Testing Range: Does it cover the high OTR of simple PE films and the ultra-low OTR of high-barrier EVOH or metallized structures?

-

Accuracy & Repeatability: Ask for validation certificates and check the standard deviation on repeat tests. Inconsistent data is worse than no data.

-

Throughput: How many samples can it run simultaneously? How long does a single test take? This directly impacts your lab's efficiency.

-

Ease of Use: Is the software intuitive? Look for features like pre-programmed test methods and remote monitoring capabilities.

-

Compliance: Ensure the instrument meets key international standards like ASTM D3985, ISO 15105-2, and ASTM F2622.

The Bottom Line

In today's competitive market, "good enough" packaging isn't good enough. Your customers trust you to deliver a product that is safe, fresh, and effective. An Oxygen Transmission Rate Tester is the definitive tool that takes the guesswork out of package integrity.

It transforms your quality assurance from a reactive process to a proactive, data-driven strategy. Don't wait for a customer complaint or a spoiled shipment to reveal a flaw in your packaging barrier. Know your numbers.

Ready to move beyond guesswork? Let's talk about how integrating precise OTR testing can safeguard your products and strengthen your brand's reputation.