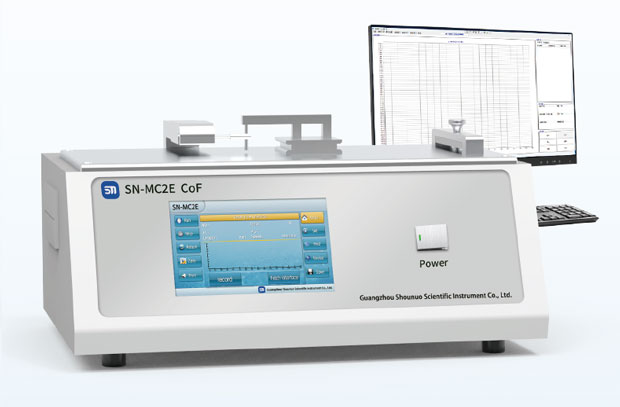

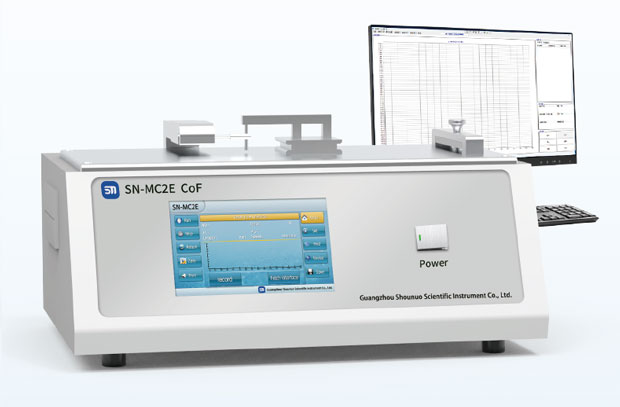

In the world of flexible packaging, ensuring product quality, safety, and efficiency is paramount. One key instrument that plays a critical role in this process is the Coefficient of Friction Tester. This device measures the slipperiness or resistance between packaging surfaces, providing valuable data that directly impacts production and performance. But what exactly does it do, and how vital is it in daily operations?

A Coefficient of Friction Tester is specifically designed to evaluate the static and kinetic friction of materials such as plastic films, laminates, and papers. These measurements help manufacturers predict how materials will behave during manufacturing, transportation, and storage. For instance, if a film has too high or too low friction, it can cause issues in packaging machines—like jamming, misalignment, or uneven sealing—leading to waste and downtime. By using a Friction Coefficient Tester, companies can optimize their material selection and process parameters to enhance machine efficiency and reduce operational costs.

Moreover, the importance of this instrument cannot be overstated. In industries where speed and precision are crucial—such as food, pharmaceuticals, and consumer goods—even minor inconsistencies in material friction can lead to significant losses. A Surface Friction Tester helps maintain consistency across batches, ensuring that every roll of packaging material meets the required specifications. This not only improves production flow but also enhances the end-user experience by preventing issues like difficult-to-open packages or unstable stacking.

But is friction testing always mandatory? While not every company may perform it on every batch, it is strongly recommended, especially for businesses that prioritize quality control and lean manufacturing. Regular use of a Coefficient of Friction Tester helps avoid unforeseen production halts and maintains compliance with industry standards. In many cases, it is a best practice that differentiates reliable suppliers from the rest.

In summary, the Coefficient of Friction Tester is more than just a quality control tool—it is a vital component for achieving operational excellence in flexible packaging. Whether referred to as a Friction Coefficient Tester or Surface Friction Tester, its function remains essential: to ensure that packaging materials perform as expected in real-world conditions. Implementing consistent friction testing is a proactive step toward reducing waste, enhancing productivity, and delivering superior products to the market.