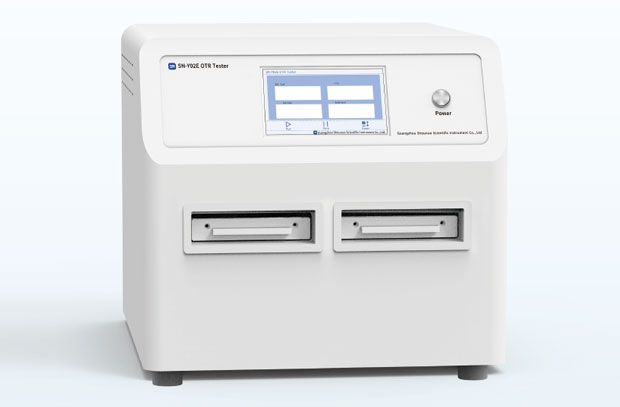

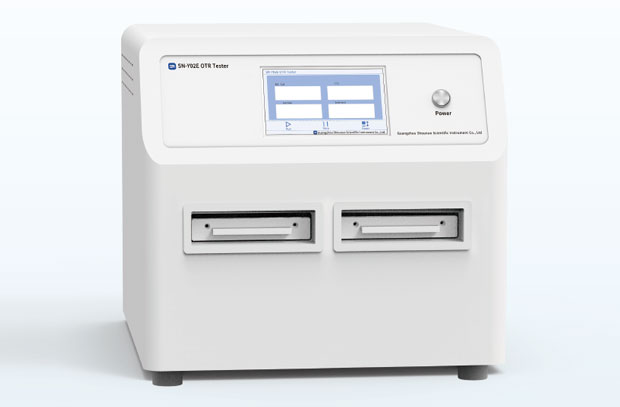

For professionals in packaging, materials science, and quality control, the integrity of a material's barrier against gases is paramount. The Gas Permeability Testing Instrument is a critical piece of equipment in this evaluation process. However, operators, both new and experienced, can sometimes encounter questions regarding its optimal use and the interpretation of results. This article aims to address some of the most common inquiries to help you ensure accurate and reliable data for your packaging quality assurance.

A frequent question that arises is about the fundamental difference between a Gas Permeability Analyzer and other similar terms. Essentially, these names often refer to the same core technology. Whether called a Gas Permeability Testing Instrument, a Gas transmittance meter, or a Gas Permeability Analyzer, the primary function remains to measure the rate at which a specific gas (such as oxygen, carbon dioxide, or nitrogen) permeates through a material over a set area and time under controlled conditions. The key is to understand the specifications of your specific instrument, as different models might be optimized for different testing standards, gas types, or material thicknesses.

Another area of common concern involves the calibration and verification of the instrument. Users often wonder how often they should calibrate their device to maintain accuracy. The answer depends on several factors, including the frequency of use, the requirements of the testing standards you adhere to, and the manufacturer's recommendations. Generally, a regular schedule of calibration using certified reference materials is non-negotiable for maintaining data integrity. A well-maintained Gas Permeability Testing Instrument not only provides precise results but also ensures compliance with international quality norms. If you notice a drift in your results or after any significant maintenance, performing a verification check is a prudent step.

The preparation and mounting of test samples is a critical step that directly impacts the outcome. Questions often surface about why test results might be inconsistent. More often than not, the issue lies in sample handling. Ensuring that the sample is clean, free of scratches, and properly cut to fit the test cell is crucial. An improper seal in the test chamber is a common source of error, allowing gas to leak and leading to inaccurately high permeability rates. When using a Gas Permeability Analyzer, always follow the manufacturer's guidelines for securing the sample to create a flawless seal between the two halves of the diffusion cell.

Interpreting the data generated by the instrument can also prompt questions. What do the final permeability values truly indicate about my material's performance? The data from a Gas transmittance meter provides a quantitative measure of the material's barrier properties. A lower permeability value signifies a better barrier, meaning the material is more effective at preventing the gas from passing through. This is vital for predicting the shelf life and preserving the quality of sensitive products, such as food and pharmaceuticals. Understanding the relationship between this data and your product's real-world performance is key to making informed material selection decisions.

Finally, users sometimes encounter operational issues, such as longer-than-expected test times. The permeability test duration is influenced by the material's barrier properties themselves. High-barrier materials, which have very low permeability, naturally require a longer time to allow a detectable amount of gas to pass through for an accurate measurement. Patience is essential, as rushing the process or attempting to use shortened test methods not validated for your material can compromise the results from your Gas Permeability Testing Instrument. For consistent and reliable operation, establishing a robust routine that includes proper calibration, meticulous sample preparation, and a clear understanding of your instrument's data output will maximize the value of your investment in gas barrier testing. This proactive approach to maintenance and operation ensures that your packaging meets the highest standards of quality and performance.