For any business involved in manufacturing or using flexible packaging, accurately determining the Water Vapor Transmission Rate (WVTR) is a non-negotiable aspect of quality assurance. Selecting the right WVTR Tester is critical, and the choice often narrows down to two prevalent technologies: the classic Single-chamber WVTR (cup method) and modern multi-chamber systems utilizing infrared sensors. Understanding the operational principles and practical implications of each type is fundamental to choosing a Water Vapor Permeation Analyzer that aligns with your lab's throughput, accuracy, and budgetary requirements.

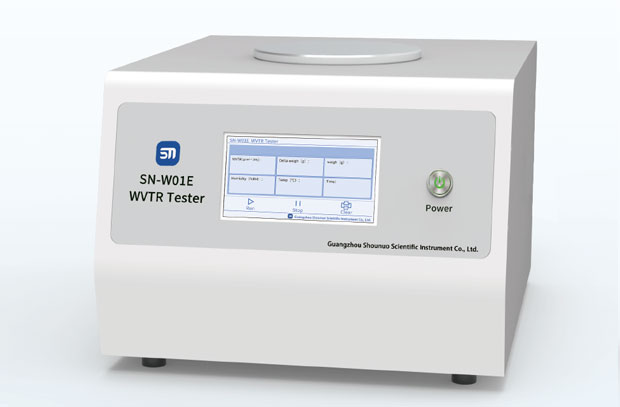

The Single-chamber WVTR (cup method) represents the foundational approach to permeation testing. Its core principle is gravimetric, meaning it relies on measuring weight change. In this setup, the film sample is sealed over a cup containing a desiccant, creating a controlled humidity differential. The entire assembly is placed in a stable environment, and its mass is meticulously tracked over time. The rate of weight gain directly correlates to the WVTR. Modern iterations of this Water Vapor Permeation Analyzer often automate the environmental control and weighing process, enhancing data consistency. This method is valued for its directness and is governed by several international standards. For labs with a lower sample volume and less stringent time constraints, a Single-chamber WVTR (cup method) system can be a cost-effective solution for validating material barriers.

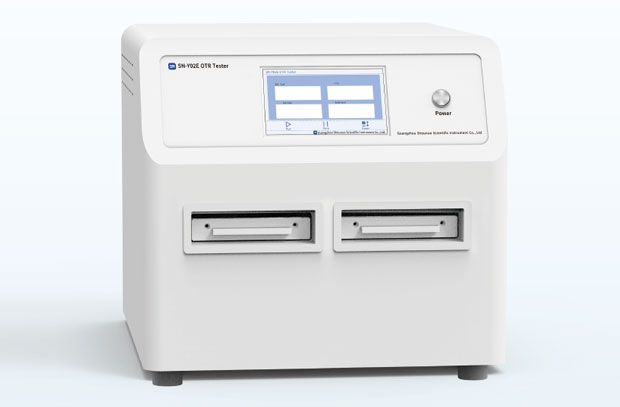

In contrast, multi-chamber infrared sensor testers represent a significant technological evolution in how water vapor is detected and quantified. This method employs a dry carrier gas, such as nitrogen, which flows across one side of the sample. Any water vapor that permeates through the material is carried by this gas stream to a highly sensitive infrared detector. The key advantage here is speed and sensitivity; the infrared sensor provides rapid, real-time data, delivering results in hours instead of the days often required by gravimetric methods. When this technology is integrated into a Flexible Packaging WVTR Tester with three independent chambers, it allows for the simultaneous testing of multiple samples. This parallel processing dramatically increases laboratory throughput and efficiency, making it an indispensable tool for high-volume QC labs and intensive R&D departments.

The practical differences between these systems directly impact laboratory workflow and capability. The primary constraint of the Single-chamber WVTR (cup method) is its testing speed, which can be a bottleneck for product development cycles requiring quick turnarounds. While extremely reliable, its lower sensitivity compared to infrared sensors may challenge the measurement of ultra-high barrier materials. The multi-chamber infrared WVTR Tester, however, excels in both speed and precision. Its automated operation minimizes manual intervention and the potential for human error. The ability to run several samples at once transforms testing capacity, providing a comprehensive data set under identical conditions much faster. This makes a modern Water Vapor Permeation Analyzer based on infrared technology a powerful asset for companies aiming to innovate and adhere to the most rigorous material specifications.

Choosing between a Single-chamber WVTR (cup method) system and a multi-chamber infrared analyzer ultimately depends on a clear assessment of your needs. If your operation involves intermittent testing, has a constrained budget, and can accommodate longer test durations, the single-chamber gravimetric approach remains a valid and standardized choice. However, for labs where time is a critical factor, where the highest level of accuracy for advanced materials is required, and where maximizing data output is a priority, the investment in a multi-chamber infrared Flexible Packaging WVTR Tester is justified. The higher throughput and superior sensitivity of the infrared system often result in a lower cost per test and a faster return on investment for busy facilities, positioning it as the modern solution for forward-thinking packaging professionals.